A | B | C | D | E | F | G | H | CH | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9

| Manhattan District | |

|---|---|

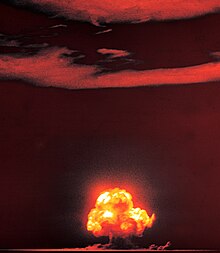

The Trinity test of the Manhattan Project on 16 July 1945 was the first detonation of a nuclear weapon. | |

| Active | 1942–1946 |

| Disbanded | 15 August 1947 |

| Country |

|

| Branch | U.S. Army Corps of Engineers |

| Garrison/HQ | Oak Ridge, Tennessee, U.S. |

| Anniversaries | 13 August 1942 |

| Engagements | |

| Commanders | |

| Notable commanders | |

| Insignia | |

| Manhattan District shoulder sleeve insignia |  |

The Manhattan Project was a research and development program undertaken during World War II to produce the first nuclear weapons. It was led by the United States in collaboration with the United Kingdom and Canada. From 1942 to 1946, the project was directed by Major General Leslie Groves of the U.S. Army Corps of Engineers. Nuclear physicist J. Robert Oppenheimer was the director of the Los Alamos Laboratory that designed the bombs. The Army program was designated the Manhattan District, as its first headquarters were in Manhattan; the name gradually superseded the official codename, Development of Substitute Materials, for the entire project. The project absorbed its earlier British counterpart, Tube Alloys. The Manhattan Project employed nearly 130,000 people at its peak and cost nearly US$2 billion (equivalent to about $27 billion in 2023),[1] over 80 percent of which was for building and operating the plants that produced the fissile material. Research and production took place at more than 30 sites across the US, the UK, and Canada.

The project resulted in two types of atomic bombs, developed concurrently during the war: a relatively simple gun-type fission weapon and a more complex implosion-type nuclear weapon. The Thin Man gun-type design proved impractical to use with plutonium, so a simpler gun-type design called Little Boy was developed that used uranium-235. Three methods were employed for uranium enrichment: electromagnetic, gaseous, and thermal. In parallel with the work on uranium was an effort to produce plutonium. After the feasibility of the world's first artificial nuclear reactor, the Chicago Pile-1, was demonstrated in 1942 at the Metallurgical Laboratory in the University of Chicago, the project designed the X-10 Graphite Reactor and the production reactors at the Hanford Site, in which uranium was irradiated and transmuted into plutonium. The Fat Man plutonium implosion-type weapon was developed in a concerted design and development effort by the Los Alamos Laboratory.

The project was also charged with gathering intelligence on the German nuclear weapon project. Through Operation Alsos, Manhattan Project personnel served in Europe, sometimes behind enemy lines, where they gathered nuclear materials and documents, and rounded up German scientists. Despite the Manhattan Project's emphasis on security, Soviet atomic spies penetrated the program.

The first nuclear device ever detonated was an implosion-type bomb during the Trinity test, conducted at White Sands Proving Ground in New Mexico on 16 July 1945. Little Boy and Fat Man bombs were used a month later in the atomic bombings of Hiroshima and Nagasaki. In the immediate postwar years, the Manhattan Project conducted weapons testing at Bikini Atoll as part of Operation Crossroads, developed new weapons, promoted the development of the network of national laboratories, supported medical research into radiology and laid the foundations for the nuclear navy. It maintained control over American atomic weapons research and production until the formation of the United States Atomic Energy Commission (UNAEC) in January 1947.

Origins

The discovery of nuclear fission by German chemists Otto Hahn and Fritz Strassmann in 1938, and its theoretical explanation by Lise Meitner and Otto Frisch, made the development of an atomic bomb a theoretical possibility. There were fears that a German atomic bomb project would develop one first, especially among scientists who were refugees from Nazi Germany and other fascist countries.[2] In August 1939, Hungarian-born physicists Leo Szilard and Eugene Wigner drafted the Einstein–Szilard letter, which warned of the potential development of "extremely powerful bombs of a new type". It urged the United States to acquire stockpiles of uranium ore and accelerate the research of Enrico Fermi and others into nuclear chain reactions.[3]

They had it signed by Albert Einstein and delivered to President Franklin D. Roosevelt. Roosevelt called on Lyman Briggs of the National Bureau of Standards to head the Advisory Committee on Uranium to investigate the issues; Briggs met with Szilard, Wigner and Edward Teller in October 1939.[3] The committee reported back to Roosevelt in November that uranium "would provide a possible source of bombs with a destructiveness vastly greater than anything now known."[4]

In February 1940, the U.S. Navy awarded Columbia University $6,000 in funding,[5] most of which Fermi and Szilard spent on graphite. A team of Columbia professors including Fermi, Szilard, Eugene T. Booth and John Dunning created the first nuclear fission reaction in the Americas, verifying the work of Hahn and Strassmann. The same team subsequently built a series of prototype nuclear reactors (or "piles" as Fermi called them) in Pupin Hall at Columbia but were not yet able to achieve a chain reaction.[6] The Advisory Committee on Uranium became the National Defense Research Committee (NDRC) on Uranium when that organization was formed on 27 June 1940.[7]

Briggs proposed spending $167,000 on research into uranium, particularly the uranium-235 isotope, and plutonium, which was discovered in 1940 at the University of California.[8][a] On 28 June 1941, Roosevelt signed Executive Order 8807, which created the Office of Scientific Research and Development (OSRD),[10] with Vannevar Bush as its director. The office was empowered to engage in large engineering projects in addition to research.[8] The NDRC Committee on Uranium became the S-1 Section of the OSRD; the word "uranium" was dropped for security reasons.[11]

In Britain, Frisch and Rudolf Peierls at the University of Birmingham had made a breakthrough investigating the critical mass of uranium-235 in June 1939.[12] Their calculations indicated that it was within an order of magnitude of 10 kilograms (22 lb), which was small enough to be carried by a bomber of the day.[13] Their March 1940 Frisch–Peierls memorandum initiated the British atomic bomb project and its MAUD Committee,[14] which unanimously recommended pursuing the development of an atomic bomb.[13] In July 1940, Britain had offered to give the United States access to its research,[15] and the Tizard Mission's John Cockcroft briefed American scientists on British developments. He discovered that the American project was smaller than the British, and not as advanced.[16]

As part of the scientific exchange, the MAUD Committee's findings were conveyed to the United States. One of its members, the Australian physicist Mark Oliphant, flew to the US in late August 1941 and discovered that data provided by the MAUD Committee had not reached key American physicists. Oliphant set out to find out why the committee's findings were apparently being ignored. He met with the Uranium Committee and visited Berkeley, California, where he spoke persuasively to Ernest O. Lawrence. Lawrence was sufficiently impressed to commence his own research into uranium. He in turn spoke to James B. Conant, Arthur H. Compton and George B. Pegram. Oliphant's mission was therefore a success; key American physicists were now aware of the potential power of an atomic bomb.[17][18]

On 9 October 1941, President Roosevelt approved the atomic program after he convened a meeting with Vannevar Bush and Vice President Henry A. Wallace. He created a Top Policy Group consisting of himself—although he never attended a meeting—Wallace, Bush, Conant, Secretary of War Henry L. Stimson, and the Chief of Staff of the Army, General George C. Marshall. Roosevelt chose the Army to run the project rather than the Navy, because the Army had more experience with management of large-scale construction. He agreed to coordinate the effort with that of the British and on 11 October sent a message to Prime Minister Winston Churchill, suggesting that they correspond on atomic matters.[19]

Feasibility

Proposals

The S-1 Committee meeting on 18 December 1941 was "pervaded by an atmosphere of enthusiasm and urgency"[20] in the wake of the attack on Pearl Harbor and the United States declaration of war on Japan and on Germany.[21] Work was proceeding on three techniques for isotope separation: Lawrence and his team at the University of California investigated electromagnetic separation, Eger Murphree and Jesse Wakefield Beams's team looked into gaseous diffusion at Columbia University, and Philip Abelson directed research into thermal diffusion at the Carnegie Institution of Washington and later the Naval Research Laboratory.[22] Murphree also headed an unsuccessful separation project using gas centrifuges.[23]

Meanwhile, there were two lines of investigation into nuclear reactor technology: Harold Urey researched heavy water at Columbia, while Arthur Compton organized the Metallurgical Laboratory in early 1942 to study plutonium and reactors using graphite as a neutron moderator.[24] The S-1 Committee recommended pursuing all five technologies. This was approved by Bush, Conant, and Brigadier General Wilhelm D. Styer, who had been designated the Army's representative on nuclear matters.[22]

Bush and Conant then took the recommendation to the Top Policy Group with a budget proposal for $54 million for construction by the United States Army Corps of Engineers, $31 million for research and development by OSRD and $5 million for contingencies in fiscal year 1943. They sent it on 17 June 1942, to the President, who approved it by writing "OK FDR" on the document.[22]

Bomb design concepts

Compton asked theoretical physicist J. Robert Oppenheimer of the University of California to take over research into fast neutron calculations—key to calculations of critical mass and weapon detonation—from Gregory Breit, who had quit on 18 May 1942 because of concerns over lax operational security.[25] John H. Manley, a physicist at the Metallurgical Laboratory, was assigned to assist Oppenheimer by coordinating experimental physics groups scattered across the country.[26] Oppenheimer and Robert Serber of the University of Illinois examined the problems of neutron diffusion—how neutrons moved in a nuclear chain reaction—and hydrodynamics—how the explosion produced by a chain reaction might behave.[27]

To review this work and the general theory of fission reactions, Oppenheimer and Fermi convened meetings at the University of Chicago in June and at the University of California in July 1942 with theoretical physicists Hans Bethe, John Van Vleck, Edward Teller, Emil Konopinski, Robert Serber, Stan Frankel, and Eldred C. (Carlyle) Nelson, and experimental physicists Emilio Segrè, Felix Bloch, Franco Rasetti, Manley, and Edwin McMillan. They tentatively confirmed that a fission bomb was theoretically possible.[27]

The properties of pure uranium-235 were relatively unknown, as were those of plutonium, which had only been discovered in February 1941 by Glenn Seaborg and his team. The scientists at the July 1942 conference envisioned creating plutonium in nuclear reactors where uranium-238 atoms absorbed neutrons that had been emitted from fissioning uranium-235. At this point no reactor had been built, and only tiny quantities of plutonium were available from cyclotrons.[28] Even by December 1943, only two milligrams had been produced.[29] There were many ways of arranging the fissile material into a critical mass. The simplest was shooting a "cylindrical plug" into a sphere of "active material" with a "tamper"—dense material to focus neutrons inward and keep the reacting mass together to increase its efficiency.[30] They also explored designs involving spheroids, a primitive form of "implosion" suggested by Richard C. Tolman, and the possibility of autocatalytic methods to increase the efficiency of the bomb as it exploded.[31]

As the idea of the fission bomb was theoretically settled—at least until more experimental data was available—Edward Teller pushed for discussion of a more powerful bomb: the "super", now usually referred to as a "hydrogen bomb", which would use the force of a detonating fission bomb to ignite a nuclear fusion reaction in deuterium and tritium.[32] Teller proposed scheme after scheme, but Bethe refused each one. The fusion idea was put aside to concentrate on producing fission bombs.[33] Teller raised the speculative possibility that an atomic bomb might "ignite" the atmosphere because of a hypothetical fusion reaction of nitrogen nuclei.[b] Bethe calculated that it was "extremely unlikely".[35] A postwar report co-authored by Teller concluded that "whatever the temperature to which a section of the atmosphere may be heated, no self-propagating chain of nuclear reactions is likely to be started."[36] In Serber's account, Oppenheimer mentioned the possibility of this scenario to Arthur Compton, who "didn't have enough sense to shut up about it. It somehow got into a document that went to Washington" and was "never laid to rest".[c]

Organization

Manhattan District

The Chief of Engineers, Major General Eugene Reybold, selected Colonel James C. Marshall to head the Army's part of the project in June 1942. Marshall created a liaison office in Washington, D.C., but established his temporary headquarters at 270 Broadway in New York, where he could draw on administrative support from the Corps of Engineers' North Atlantic Division. It was close to the Manhattan office of Stone & Webster, the principal project contractor, and to Columbia University. He had permission to draw on his former command, the Syracuse District, for staff, and he started with Lieutenant Colonel Kenneth Nichols, who became his deputy.[38][39]

Because most of his task involved construction, Marshall worked in cooperation with the head of the Corps of Engineers Construction Division, Major General Thomas M. Robbins, and his deputy, Colonel Leslie Groves. Reybold, Somervell, and Styer decided to call the project "Development of Substitute Materials", but Groves felt that this would draw attention. Since engineer districts normally carried the name of the city where they were located, Marshall and Groves agreed to name the Army's component the Manhattan District; Reybold officially created this district on 13 August. Informally, it was known as the Manhattan Engineer District, or MED. Unlike other districts, it had no geographic boundaries, and Marshall had the authority of a division engineer. Development of Substitute Materials remained as the official codename of the project as a whole but was supplanted over time by "Manhattan".[39][40]

Marshall later conceded that, "I had never heard of atomic fission but I did know that you could not build much of a plant, much less four of them for $90 million."[41] A single TNT plant that Nichols had recently built in Pennsylvania had cost $128 million.[42] Nor were they impressed with estimates to the nearest order of magnitude, which Groves compared with telling a caterer to prepare for between ten and a thousand guests.[43] A survey team from Stone & Webster had already scouted a site for the production plants. The War Production Board recommended sites around Knoxville, Tennessee, an isolated area where the Tennessee Valley Authority could supply ample electric power and the rivers could provide cooling water for the reactors. After examining several sites, the survey team selected one near Elza, Tennessee. Conant advised that it be acquired at once and Styer agreed but Marshall temporized, awaiting the results of Conant's reactor experiments.[44] Of the prospective processes, only Lawrence's electromagnetic separation appeared sufficiently advanced for construction to commence.[45]

Marshall and Nichols began assembling the necessary resources. The first step was to obtain a high priority rating for the project. The top ratings were AA-1 through AA-4 in descending order, although there was a special AAA rating reserved for emergencies. Ratings AA-1 and AA-2 were for essential weapons and equipment, so Colonel Lucius D. Clay, the deputy chief of staff at Services and Supply for requirements and resources, felt that the highest rating he could assign was AA-3, although he was willing to provide a AAA rating on request for critical materials if the need arose.[46] Nichols and Marshall were disappointed; AA-3 was the same priority as Nichols' TNT plant in Pennsylvania.[47]

Military Policy Committee

Vannevar Bush became dissatisfied with Colonel Marshall's failure to get the project moving forward expeditiously[49] and felt that more aggressive leadership was required. He spoke to Harvey Bundy and Generals Marshall, Somervell, and Styer about his concerns, advocating that the project be placed under a senior policy committee, with a prestigious officer, preferably Styer, as director.[47]

Somervell and Styer selected Groves for the post; General Marshall ordered that he be promoted to brigadier general,[50] as it was felt that the title "general" would hold more sway with the academic scientists working on the project.[51] Groves' orders placed him directly under Somervell rather than Reybold, with Colonel Marshall now answerable to Groves.[52] Groves established his headquarters in Washington, D.C., in the New War Department Building, where Colonel Marshall had his liaison office.[53] He assumed command of the Manhattan Project on 23 September 1942. Later that day, he attended a meeting called by Stimson, which established a Military Policy Committee, responsible to the Top Policy Group, consisting of Bush (with Conant as an alternate), Styer and Rear Admiral William R. Purnell.[50] Tolman and Conant were later appointed as Groves' scientific advisers.[54]

On 19 September, Groves went to Donald Nelson, the chairman of the War Production Board, and asked for broad authority to issue a AAA rating whenever it was required. Nelson initially balked but quickly caved in when Groves threatened to go to the President.[55] Groves promised not to use the AAA rating unless it was necessary. It soon transpired that for the routine requirements of the project the AAA rating was too high but the AA-3 rating was too low. After a long campaign, Groves finally received AA-1 authority on 1 July 1944.[56] According to Groves, "In Washington you became aware of the importance of top priority. Most everything proposed in the Roosevelt administration would have top priority. That would last for about a week or two and then something else would get top priority".[57]

One of Groves' early problems was to find a director for Project Y, the group that would design and build the bomb. The obvious choice was one of the three laboratory heads, Urey, Lawrence, or Compton, but they could not be spared. Compton recommended Oppenheimer, who was already intimately familiar with the bomb design concepts. However, Oppenheimer had little administrative experience, and, unlike Urey, Lawrence, and Compton, had not won a Nobel Prize, which many scientists felt that the head of such an important laboratory should have. There were also concerns about Oppenheimer's security status, as many of his associates were communists, including his wife, Kitty; his girlfriend, Jean Tatlock; and his brother, Frank. A long conversation in October 1942 convinced Groves and Nichols that Oppenheimer thoroughly understood the issues involved in setting up a laboratory in a remote area and should be appointed as its director. Groves personally waived the security requirements and issued Oppenheimer's clearance on 20 July 1943.[58][59]

Collaboration with the United Kingdom

The British and Americans exchanged nuclear information but did not initially combine their efforts; during 1940-41 the British project (Tube Alloys) was larger and more advanced.[16] Britain rebuffed attempts by Bush and Conant in August 1941 to strengthen cooperation because it was reluctant to share its technological lead and help the United States develop its own atomic bomb. But the British, who had made significant advances in research early in the war, did not have the resources to carry through such a research program into development while a large portion of their economy was engaged in fighting the war; Tube Alloys soon fell behind its American counterpart.[60] The roles of the two countries were reversed,[61] and in January 1943 Conant notified the British that they would no longer receive atomic information except in certain areas.[62][63] The British investigated the possibility of an independent nuclear program but determined that it could not be ready in time to impact the war in Europe.[64]

By March 1943 Conant decided that James Chadwick and one or two other British scientists were important enough that the bomb design team at Los Alamos needed them, despite the risk of revealing weapon design secrets.[65] In August 1943 Churchill and Roosevelt negotiated the Quebec Agreement,[66][67] which established the Combined Policy Committee to coordinate the efforts of the US and UK; Canada was not a signatory, but the Agreement provided for a Canadian representative on the Combined Policy Committee in view of Canada's contribution to the effort.[68] An agreement between Roosevelt and Churchill known as the Hyde Park Aide-Mémoire, signed in late September 1944, extended the Quebec Agreement to the postwar period and suggested that "when a 'bomb' is finally available, it might perhaps, after mature consideration, be used against the Japanese, who should be warned that this bombardment will be repeated until they surrender".[69][70]

When cooperation resumed after the Quebec Agreement, the Americans' progress and expenditures amazed the British. Chadwick pressed for British involvement in the Manhattan Project to the fullest extent and abandoned hopes of an independent British project during the war.[64] With Churchill's backing, he attempted to ensure that every request from Groves for assistance was honored.[71] The British Mission that arrived in the United States in December 1943 included Niels Bohr, Otto Frisch, Klaus Fuchs, Rudolf Peierls, and Ernest Titterton.[72] More scientists arrived in early 1944. While those assigned to gaseous diffusion left by the fall of 1944, the thirty-five working under Oliphant with Lawrence at Berkeley were assigned to existing laboratory groups and most stayed until the end of the war. The nineteen sent to Los Alamos also joined existing groups, primarily related to implosion and bomb assembly, but not the plutonium-related ones.[64] The Quebec Agreement specified that nuclear weapons would not be used against another country without the mutual consent of the US and UK. In June 1945, Wilson agreed that the nuclear bombing of Japan would be recorded as a decision of the Combined Policy Committee.[73]

The Combined Policy Committee created the Combined Development Trust in June 1944, with Groves as its chairman, to procure uranium and thorium ores on international markets. The Belgian Congo and Canada held much of the world's uranium outside Eastern Europe, and the Belgian Government in Exile was in London. Britain agreed to give the United States most of the Belgian ore, as it could not use most of the supply without restricted American research.[74] In 1944, the Trust purchased 3,440,000 pounds (1,560,000 kg) of uranium oxide ore from companies operating mines in the Belgian Congo. To avoid briefing US Secretary of the Treasury Henry Morgenthau Jr., a special account not subject to the usual auditing and controls was used to hold Trust monies. Between 1944 and his resignation from the Trust in 1947, Groves deposited a total of $37.5 million.[75]

Groves appreciated the early British atomic research and the British scientists' contributions to the Manhattan Project but stated that the United States would have succeeded without them, although not in time for the August 1945 bombing of Hiroshima.[76] The British wartime participation was crucial to the success of the United Kingdom's independent nuclear weapons program after the war when the McMahon Act of 1946 temporarily ended American nuclear cooperation.[64]

Project sites

Oak Ridge

The day after he took over the project, Groves went to Tennessee with Colonel Marshall to inspect the proposed site there, and Groves was impressed.[78][79] On 29 September 1942, United States Under Secretary of War Robert P. Patterson authorized the Corps of Engineers to acquire 56,000 acres (23,000 ha) of land by eminent domain at a cost of $3.5 million. An additional 3,000 acres (1,200 ha) was subsequently acquired. About 1,000 families were affected by the order, which came into effect on 7 October.[80] Protests, legal appeals, and a 1943 Congressional inquiry were to no avail.[81] By mid-November U.S. Marshals were posting notices to vacate on farmhouse doors, and construction contractors were moving in.[82] Some families were given two weeks' notice to vacate farms that had been their homes for generations.[83] The ultimate cost of the land acquisition, which was not completed until March 1945, was only about $2.6 million—around $47 an acre.[84] When presented with a proclamation declaring Oak Ridge a total exclusion area that no one could enter without military permission, the Governor of Tennessee, Prentice Cooper, angrily tore it up.[85]

Initially known as the Kingston Demolition Range, the site was officially renamed the Clinton Engineer Works (CEW) in early 1943.[86] While Stone & Webster concentrated on the production facilities, the architectural and engineering firm Skidmore, Owings & Merrill developed a residential community for 13,000. The community was located on the slopes of Black Oak Ridge, from which the new town of Oak Ridge got its name.[87] The Army presence at Oak Ridge increased in August 1943 when Nichols replaced Marshall as head of the Manhattan Engineer District. One of his first tasks was to move the district headquarters to Oak Ridge, although the name of the district did not change.[88] In September 1943 the administration of community facilities was outsourced to Turner Construction Company through a subsidiary, the Roane-Anderson Company.[89] Chemical engineers were part of "frantic efforts" to make 10% to 12% enriched uranium 235, with tight security and fast approvals for supplies and materials.[90] The population of Oak Ridge soon expanded well beyond the initial plans, and peaked at 75,000 in May 1945, by which time 82,000 people were employed at the Clinton Engineer Works,[77] and 10,000 by Roane-Anderson.[89]

Los Alamos

The idea of locating Project Y at Oak Ridge was considered, but it was decided that it should be in a remote location. On Oppenheimer's recommendation, the search for a suitable site was narrowed to the vicinity of Albuquerque, New Mexico, where Oppenheimer owned a ranch.[91] On 16 November 1942, Oppenheimer, Groves, Dudley and others toured the vicinity of the Los Alamos Ranch School. Oppenheimer expressed a strong preference for the site, citing its natural beauty, which, it was hoped, would inspire those working on the project.[92][93] The engineers were concerned about the poor access road, and whether the water supply would be adequate, but otherwise felt that it was ideal.[94]

Patterson approved the acquisition of the site on 25 November 1942, authorizing $440,000 for the purchase of 54,000 acres (22,000 ha), all but 8,900 acres (3,600 ha) of which were already owned by the Federal Government.[95] Secretary of Agriculture Claude R. Wickard granted 45,100 acres (18,300 ha) of United States Forest Service land to the War Department "for so long as the military necessity continues".[96] Wartime land purchases eventually came to 45,737 acres (18,509.1 ha), but only $414,971 was spent.[95] Work commenced in December 1942. Groves initially allocated $300,000 for construction, three times Oppenheimer's estimate, but by the time Sundt finished on 30 November 1943, over $7 million had been spent.[97]

During the war, Los Alamos was referred to as "Site Y" or "the Hill".[98] Initially it was to have been a military laboratory with Oppenheimer and other researchers commissioned into the Army, but Robert Bacher and Isidor Rabi balked at the idea and convinced Oppenheimer that other scientists would object. Conant, Groves, and Oppenheimer then devised a compromise whereby the laboratory was operated by the University of California under contract to the War Department.[99] Dorothy McKibbin ran the branch office in Santa Fe, where she met new arrivals and issue them with passes.[100]

Chicago

An Army-OSRD council on 25 June 1942 decided to build a pilot plant for plutonium production in the Argonne Forest preserve, southwest of Chicago. In July, Nichols arranged for a lease of 1,025 acres (415 ha) from the Cook County Forest Preserve District, and Captain James F. Grafton was appointed Chicago area engineer. It soon became apparent that the scale of operations was too great for the area, and it was decided to build the pilot plant at Oak Ridge and keep a research and testing facility in Chicago.[101][102]

Delays in establishing the plant at Argonne led Arthur Compton to authorize the Metallurgical Laboratory to construct the first nuclear reactor beneath the bleachers of Stagg Field at the University of Chicago. The reactor required an enormous amount of highly purified graphite blocks and uranium in both metallic and powdered oxide forms. At the time, there was a limited source of pure uranium metal; Frank Spedding of Iowa State University was able to produce only two short tons. Three short tons was supplied by Westinghouse Lamp Plant, produced in a rush with makeshift process. A large square balloon was constructed by Goodyear Tire to encase the reactor.[103][104]

On 2 December 1942, a team led by Enrico Fermi initiated the first artificial[d] self-sustaining nuclear chain reaction in an experimental reactor known as Chicago Pile-1.[106] The point at which a reaction becomes self-sustaining became known as "going critical". Compton reported the success to Conant in Washington, D.C., by a coded phone call, saying, "The Italian navigator has just landed in the new world."[107][e]

In January 1943, Grafton's successor, Major Arthur V. Peterson, ordered Chicago Pile-1 dismantled and reassembled at the Argonne Forest site, as he regarded the operation of a reactor as too hazardous for a densely populated area.[108] The new site, still operated by the Metallurgical Laboratory, became known as 'Site A'. Chicago Pile-3, the first heavy water reactor, also went critical at this site, on 15 May 1944.[109][110] After the war, operations at Site A were moved about 6 miles (9.7 km) to DuPage County, the current location of the Argonne National Laboratory.[102]

Hanford

By December 1942 there were concerns that even Oak Ridge was too close to a major population center (Knoxville) in the unlikely event of a major nuclear accident. Groves recruited DuPont in November 1942 to be the prime contractor for the construction of the plutonium production complex. The President of the company, Walter S. Carpenter Jr., wanted no profit of any kind; for legal reasons a nominal fee of one dollar was agreed upon.[111]

DuPont recommended that the site be located far from the existing uranium production facility at Oak Ridge.[112] In December 1942, Groves dispatched Colonel Franklin Matthias and DuPont engineers to scout potential sites. Matthias reported that Hanford Site near Richland, Washington, was "ideal in virtually all respects". It was isolated and near the Columbia River, which could supply sufficient water to cool the reactors. Groves visited the site in January and established the Hanford Engineer Works (HEW), codenamed "Site W".[113]

Under Secretary Patterson gave his approval on 9 February, allocating $5 million for the acquisition of 430,000 acres (170,000 ha). The federal government relocated some 1,500 residents of nearby settlements, as well as the Wanapum and other tribes using the area. A dispute arose with farmers over compensation for crops, which had already been planted. Where schedules allowed, the Army allowed the crops to be harvested, but this was not always possible.[113] The land acquisition process dragged on and was not completed before the end of the Manhattan Project in December 1946.[114]

The dispute did not delay work. Although progress on the reactor design at Metallurgical Laboratory and DuPont was not sufficiently advanced to accurately predict the scope of the project, a start was made in April 1943 on facilities for an estimated 25,000 workers, half of whom were expected to live on-site. By July 1944, some 1,200 buildings had been erected and nearly 51,000 people were living in the construction camp. As area engineer, Matthias exercised overall control of the site.[115] At its peak, the construction camp was the third most populous town in Washington state.[116] Hanford operated a fleet of over 900 buses, more than the city of Chicago.[117] Like Los Alamos and Oak Ridge, Richland was a gated community with restricted access, but it looked more like a typical wartime American boomtown: the military profile was lower, and physical security elements like high fences and guard dogs were less evident.[118]

Canadian sites

Canada provided research, extraction and production of uranium and plutonium, and Canadian scientists worked at Los Alamos.[119][120]

British Columbia

Cominco had produced electrolytic hydrogen at Trail, British Columbia, since 1930. Urey suggested in 1941 that it could produce heavy water. To the existing $10 million plant consisting of 3,215 cells consuming 75 MW of hydroelectric power, secondary electrolysis cells were added to increase the deuterium concentration in the water from 2.3% to 99.8%. For this process, Hugh Taylor of Princeton developed a platinum-on-carbon catalyst for the first three stages while Urey developed a nickel-chromia one for the fourth stage tower. The final cost was $2.8 million. The Canadian Government did not officially learn of the project until August 1942. Trail's heavy water production started in January 1944 and continued until 1956. Heavy water from Trail was used for Chicago Pile 3, the first reactor using heavy water and natural uranium, which went critical on 15 May 1944.[121]

Ontario

The Chalk River, Ontario, site was established to rehouse the Allied effort at the Montreal Laboratory away from an urban area. A new community was built at Deep River, Ontario, to provide residences and facilities for the team members. The site was chosen for its proximity to the industrial manufacturing area of Ontario and Quebec, and proximity to a rail head adjacent to a large military base, Camp Petawawa. Located on the Ottawa River, it had access to abundant water. The first director of the new laboratory was Hans von Halban. He was replaced by John Cockcroft in May 1944, who was succeeded by Bennett Lewis in September 1946. A pilot reactor known as ZEEP (zero-energy experimental pile) became the first Canadian reactor, and the first to be completed outside the United States, when it went critical in September 1945; ZEEP remained in use by researchers until 1970.[122] A larger 10 MW NRX reactor, which was designed during the war, was completed and went critical in July 1947.[121]

Northwest Territories

The Eldorado Mine at Port Radium was a source of uranium ore.[123]

Heavy water sites

Although DuPont's preferred designs for the nuclear reactors were helium cooled and used graphite as a moderator, DuPont still expressed an interest in using heavy water as a backup. The P-9 Project was the government's codename for the heavy water production program. It was estimated that 3 short tons (2.7 t) of heavy water would be required per month. The plant at Trail, then under construction, could produce 0.5 short tons (0.45 t) per month. Groves therefore authorized DuPont to establish heavy water facilities at the Morgantown Ordnance Works, near Morgantown, West Virginia; at the Wabash River Ordnance Works, near Dana and Newport, Indiana; and at the Alabama Ordnance Works, near Childersburg and Sylacauga, Alabama. Although known as Ordnance Works and paid for under Ordnance Department contracts, they were built and operated by the Army Corps of Engineers. The American plants used a process different from Trail's; heavy water was extracted by distillation, taking advantage of the slightly higher boiling point of heavy water.[124][125]

Uranium

Ore

The key raw material for the project was uranium, which was used as fuel for the reactors, as feed that was transformed into plutonium, and, in its enriched form, in the atomic bomb itself. There were four known major deposits of uranium in 1940: in Colorado, in northern Canada, in Joachimsthal in Czechoslovakia, and in the Belgian Congo.[126] All but Joachimstal were in Allied hands. A 1942 survey determined that sufficient quantities of uranium were available to satisfy the project's requirements.[127][f] Nichols arranged with the State Department for export controls to be placed on uranium oxide and negotiated for the purchase of 1,200 short tons (1,100 t) of uranium ore from the Belgian Congo that was being stored in a warehouse on Staten Island and the remaining stocks of mined ore stored in the Congo. He negotiated with Eldorado Gold Mines for the purchase of ore from its refinery in Port Hope, Ontario. The Canadian government subsequently bought up the company's stock until it acquired a controlling interest.[129]

Of these ores, those from the Belgian Congo contained the most uranium per mass of rock by far.[130][g] Beyond their wartime needs, American and British leaders concluded that it was in their countries' interest to control as much of the world's uranium deposits as possible. The Shinkolobwe mine was flooded and closed, and Nichols unsuccessfully attempted to negotiate its reopening and the sale of the entire future output to the United States with Edgar Sengier, the director of the company that owned the mine, the Union Minière du Haut-Katanga.[133] The matter was then taken up by the Combined Policy Committee. As 30 percent of Union Minière's stock was controlled by British interests, the British took the lead in negotiations. Sir John Anderson and Ambassador John Winant hammered out a deal with Sengier and the Belgian government in May 1944 for the mine to be reopened and 1,720 short tons (1,560 t) of ore to be purchased at $1.45 a pound.[134] To avoid dependence on the British and Canadians for ore, Groves also arranged for the purchase of US Vanadium Corporation's stockpile in Uravan, Colorado.[135]

The raw ore was dissolved in nitric acid to produce uranyl nitrate, which was processed into uranium trioxide, which was reduced to highly pure uranium dioxide.[136] By July 1942, Mallinckrodt was producing a ton of highly pure oxide a day, but turning this into uranium metal initially proved more difficult.[137] Production was too slow and quality was unacceptably low. A branch of the Metallurgical Laboratory was established at Iowa State College in Ames, Iowa, under Frank Spedding to investigate alternatives. This became known as the Ames Project, and its Ames process became available in 1943.[138]

Isotope separation

Natural uranium consists of 99.3% uranium-238 and 0.7% uranium-235, but as only the latter is fissile it must be physically separated from the more plentiful isotope. Various methods were considered for uranium enrichment, most of which was carried out at Oak Ridge.[139] The most obvious technology, the centrifuge, failed, but electromagnetic separation, gaseous diffusion, and thermal diffusion technologies were all successful and contributed to the project. In February 1943, Groves came up with the idea of using the output of some plants as the input for others.[140]

Centrifuges

The centrifuge process was regarded as the only promising separation method in April 1942.[141] Jesse Beams had developed such a process in the 1930s, but had encountered technical difficulties. In 1941 he began working with uranium hexafluoride, the only known gaseous compound of uranium, and was able to separate uranium-235. At Columbia, Karl P. Cohen produced a body of mathematical theory making it possible to design a centrifugal separation unit, which Westinghouse undertook to construct.[142]

Scaling this up to a production plant presented a formidable technical challenge. Urey and Cohen estimated that producing a kilogram (2.2 lb) of uranium-235 per day would require up to 50,000 centrifuges with 1-meter (3 ft 3 in) rotors, or 10,000 centrifuges with 4-meter (13 ft) rotors, assuming that 4-meter rotors could be built. The prospect of keeping so many rotors operating continuously at high speed appeared daunting,[143] and when Beams ran his experimental apparatus, he obtained only 60% of the predicted yield, indicating that more centrifuges were required. Beams, Urey and Cohen then began work on a series of improvements which promised to increase efficiency. However, frequent failures of motors, shafts and bearings at high speeds delayed work on the pilot plant.[144]

In November 1942 the centrifuge process was abandoned by the Military Policy Committee.[145] Successful gas centrifuges of the Zippe-type design were instead developed in the Soviet Union after the war. It eventually became the preferred method of uranium isotope separation, being far more economical.[146]

Electromagnetic separation

Electromagnetic isotope separation was developed at the University of California Radiation Laboratory. This method employed devices known as calutrons. The name was derived from the words California, university and cyclotron.[147] In the electromagnetic process, a magnetic field deflected charged particles according to mass.[148] The process was neither scientifically elegant nor industrially efficient.[149] Compared with a gaseous diffusion plant or a nuclear reactor, an electromagnetic separation plant would consume more scarce materials, require more manpower to operate, and cost more to build. Nonetheless, the process was approved because it was based on proven technology and therefore represented less risk. Moreover, it could be built in stages, and rapidly reach industrial capacity.[147]

Marshall and Nichols discovered that the electromagnetic isotope separation process would require 5,000 short tons (4,500 tonnes) of copper, which was in desperately short supply. However, silver could be substituted, in an 11:10 copper to silver ratio. On 3 August 1942, Nichols met with Under Secretary of the Treasury Daniel W. Bell and asked for the transfer of 6,000 tons of silver bullion from the West Point Bullion Depository.[150] Ultimately 14,700 short tons (13,300 tonnes; 430,000,000 troy ounces) were used.[151] The 1,000-troy-ounce (31 kg) silver bars were cast into cylindrical billets, extruded into strips, and wound onto magnetic coils.[151][152]

Responsibility for the design and construction of the electromagnetic separation plant, which came to be called Y-12, was assigned to Stone & Webster in June 1942. The design called for five first-stage processing units, known as Alpha racetracks, and two units for final processing, known as Beta racetracks. In September 1943 Groves authorized construction of four more racetracks, known as Alpha II. Construction began in February 1943.[154] The second Alpha I was operational at the end of January 1944, the first Beta and first and third Alpha I's came online in March, and the fourth Alpha I was operational in April. The four Alpha II racetracks were completed between July and October 1944.[155] Tennessee Eastman was contracted to manage Y-12.[156] The calutrons were turned over to trained Tennessee Eastman operators known as the Calutron Girls.[157]

The calutrons initially enriched the uranium-235 content to between 13% and 15%, and shipped the first few hundred grams of this to Los Alamos in March 1944. Only 1 part in 5,825 of the uranium feed emerged as product. Much of the rest was splattered over equipment in the process. Strenuous recovery efforts helped raise production to 10% of the uranium-235 feed by January 1945. In February the Alpha racetracks began receiving slightly enriched (1.4%) feed from the new S-50 thermal diffusion plant, and the next month they received enhanced (5%) feed from the K-25 gaseous diffusion plant. By August, K-25 was producing uranium sufficiently enriched to feed directly into the Beta tracks.[158]

Gaseous diffusion

The most promising but also the most challenging method of isotope separation was gaseous diffusion. Graham's law states that the rate of effusion of a gas is inversely proportional to the square root of its molecular mass, so in a box containing a semi-permeable membrane and a mixture of two gases, the lighter molecules will pass out of the container more rapidly than the heavier molecules. The idea was that such boxes could be formed into a cascade of pumps and membranes, with each successive stage containing a slightly more enriched mixture. Research into the process was carried out at Columbia University by a group that included Harold Urey, Karl P. Cohen, and John R. Dunning.[159]

In November 1942 the Military Policy Committee approved the construction of a 600-stage gaseous diffusion plant.[160] On 14 December, M. W. Kellogg accepted an offer to construct the plant, which was codenamed K-25. A separate corporate entity called Kellex was created for the project.[161] The process faced formidable technical difficulties. The highly corrosive gas uranium hexafluoride had to be used as no substitute could be found, and the motors and pumps had to be vacuum tight and enclosed in inert gas. The biggest problem was the design of the barrier, which had to be strong, porous and resistant to corrosion. Edward Adler and Edward Norris created a mesh barrier from electroplated nickel. A six-stage pilot plant was built at Columbia to test the process, but the prototype proved to be too brittle. A rival barrier was developed from powdered nickel by Kellex, the Bell Telephone Laboratories and the Bakelite Corporation. In January 1944, Groves ordered the Kellex barrier into production.[162][163]

Kellex's design for K-25 called for a four-story 0.5-mile (0.80 km) long U-shaped structure containing 54 contiguous buildings. These were divided into nine sections containing cells of six stages. A survey party began construction by marking out the 500-acre (2.0 km2) site in May 1943. Work on the main building began in October 1943, and the six-stage pilot plant was ready for operation on 17 April 1944. In 1945 Groves canceled the upper stages, directing Kellex to instead design and build a 540-stage side feed unit, which became known as K-27. Kellex transferred the last unit to the operating contractor, Union Carbide and Carbon, on 11 September 1945. The total cost, including the K-27 plant completed after the war, came to $480 million.[164]

The production plant commenced operation in February 1945, and as cascade after cascade came online, the quality of the product increased. By April 1945, K-25 had attained a 1.1% enrichment, and the output of the S-50 thermal diffusion plant began being used as feed. Some product produced the next month reached nearly 7% enrichment. In August, the last of the 2,892 stages commenced operation. K-25 and K-27 achieved their full potential in the early postwar period, when they eclipsed the other production plants and became the prototypes for a new generation of plants.[165]

Thermal diffusion

The thermal diffusion process was based on Sydney Chapman and David Enskog's theory, which explained that when a mixed gas passes through a temperature gradient, the heavier one tends to concentrate at the cold end and the lighter one at the warm end.[166] It was developed by US Navy scientists, but was not one of the enrichment technologies initially selected for use in the Manhattan Project. This was primarily due to doubts about its technical feasibility, but the inter-service rivalry between the Army and Navy also played a part.[167] The Naval Research Laboratory continued the research under Philip Abelson's direction, but there was little contact with the Manhattan Project until April 1944, when Captain William S. Parsons, the naval officer in charge of ordnance development at Los Alamos, brought Oppenheimer news of encouraging progress on thermal diffusion. Oppenheimer informed Groves, who approved construction of a thermal plant on 24 June 1944.[168]

Groves contracted with the H. K. Ferguson Company of Cleveland, Ohio, to build the thermal diffusion plant, which was designated S-50.[169] Plans called for the installation of 2,142 48-foot-tall (15 m) diffusion columns arranged in 21 racks. Inside each column were three concentric tubes. Steam, obtained from the nearby K-25 powerhouse at a pressure of 100 pounds per square inch (690 kPa) and temperature of 545 °F (285 °C), flowed downward through the innermost 1.25-inch (32 mm) nickel pipe, while water at 155 °F (68 °C) flowed upward through the outermost iron pipe. The uranium hexafluoride flowed in the middle copper pipe, and isotope separation of the uranium occurred between the nickel and copper pipes.[170] Work commenced on 9 July 1944, and S-50 began partial operation in September. Leaks limited production and forced shutdowns over the next few months, but in June 1945 the S-50 plant produced 12,730 pounds (5,770 kg) of slightly enriched product.[171]

By March 1945, all 21 production racks were operating. Initially the output of S-50 was fed into Y-12, but starting in March 1945 all three enrichment processes were run in series. S-50 became the first stage, enriching the uranium from 0.71% to 0.89% uranium-235. This was then fed into the gaseous diffusion process in the K-25 plant, which produced a product enriched to about 23%. In turn, this was fed into Y-12,[172] which boosted it to about 89%, sufficient for use in nuclear weapons. About 50 kilograms (110 lb) of uranium enriched to 89% was delivered to Los Alamos by July 1945. The entire 50 kg, along with some 50%-enriched, averaging out to about 85% enriched, were used in the first Little Boy bomb.[173]

Plutonium

The second line of development pursued by the Manhattan Project used plutonium. Although small amounts of plutonium exist in nature, the best way to obtain large quantities is via a reactor. Natural uranium is bombarded by neutrons and transmuted into uranium-239, which rapidly decays, first into neptunium-239 and then into plutonium-239.[174] As only a small amount will be transformed, the plutonium must be chemically separated from the remaining uranium, from any initial impurities, and from fission products.[174]

X-10 Graphite Reactor

In March 1943, DuPont began construction of a plutonium plant on a 112-acre (0.5 km2) site at Oak Ridge. Intended as a pilot plant for the larger production facilities at Hanford, it included the air-cooled X-10 Graphite Reactor, a chemical separation plant, and support facilities. Because of the subsequent decision to construct water-cooled reactors at Hanford, only the chemical separation plant operated as a true pilot.[175] The X-10 Graphite Reactor consisted of a huge block of graphite, 24 feet (7.3 m) per side, weighing around 1,500 short tons (1,400 t), surrounded by 7 feet (2.1 m) of high-density concrete as a radiation shield.[175]

The greatest difficulty was encountered with the uranium slugs produced by Mallinckrodt and Metal Hydrides. These had to be coated in aluminum to avoid corrosion and the escape of fission products into the cooling system. The Grasselli Chemical Company attempted to develop a hot dipping process without success. Alcoa tried canning, developing a new process for flux-less welding; 97% of the cans passed a standard vacuum test, but high temperature tests indicated a failure rate of more than 50%. Nonetheless, production began in June 1943. The Metallurgical Laboratory eventually developed an improved welding technique with the help of General Electric, which was incorporated into the production process in October 1943.[176]

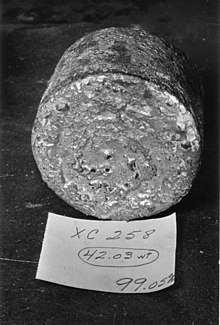

The X-10 Graphite Reactor went critical on 4 November 1943 with about 30 short tons (27 t) of uranium. A week later the load was increased to 36 short tons (33 t), raising its power generation to 500 kW, and by the end of the month the first 500 mg of plutonium was created.[177] Gradual modifications raised the power to 4,000 kW in July 1944. X-10 operated as a production plant until January 1945, when it was turned over to research.[178]

Hanford reactors

Although an air-cooled design was chosen for the reactor at Oak Ridge to facilitate rapid construction, this was impractical for the much larger production reactors. Initial designs by the Metallurgical Laboratory and DuPont used helium for cooling, before they determined that a water-cooled reactor was simpler, cheaper and quicker to build.[179] The design did not become available until 4 October 1943; in the meantime, Matthias concentrated on improving the Hanford Site by erecting accommodations, improving the roads, building a railway switch line, and upgrading the electricity, water and telephone lines.[180]

As at Oak Ridge, the most difficulty was encountered while canning the uranium slugs, which commenced at Hanford in March 1944. They were pickled to remove dirt and impurities, dipped in molten bronze, tin, and aluminum-silicon alloy, canned using hydraulic presses, and then capped using arc welding under an argon atmosphere. Finally, they were tested to detect holes or faulty welds. Disappointingly, most canned slugs initially failed the tests, resulting in an output of only a handful per day. But steady progress was made and by June 1944 production increased to the point where it appeared that enough canned slugs was available to start Reactor B on schedule in August 1944.[181]

Work began on Reactor B, the first of six planned 250 MW reactors, on 10 October 1943.[182] The reactor complexes were given letter designations A through F, with B, D and F sites developed first, as this maximized the distance between the reactors. They were the only ones constructed during the Manhattan Project.[183] Some 390 short tons (350 t) of steel, 17,400 cubic yards (13,300 m3) of concrete, 50,000 concrete blocks and 71,000 concrete bricks were used to construct the 120-foot (37 m) high building.

Construction of the reactor itself commenced in February 1944.[184] Watched by Compton, Matthias, DuPont's Crawford Greenewalt, Leona Woods and Fermi, who inserted the first slug, the reactor was powered up beginning on 13 September 1944. Over the next few days, 838 tubes were loaded and the reactor went critical. Shortly after midnight on 27 September, the operators began to withdraw the control rods to initiate production. At first all appeared well but around 03:00 the power level started to drop and by 06:30 the reactor had shut down completely. The cooling water was investigated to see if there was a leak or contamination. The next day the reactor started up again, only to shut down once more.[185][186]

Fermi contacted Chien-Shiung Wu, who identified the cause of the problem as neutron poisoning from xenon-135, which has a half-life of 9.2 hours.[187] Fermi, Woods, Donald J. Hughes and John Archibald Wheeler then calculated the nuclear cross section of xenon-135, which turned out to be 30,000 times that of uranium.[188] DuPont engineer George Graves had deviated from the Metallurgical Laboratory's original design in which the reactor had 1,500 tubes arranged in a circle, and had added an additional 504 tubes to fill in the corners. The scientists had originally considered this overengineering a waste of time and money, but Fermi realized that by loading all 2,004 tubes, the reactor could reach the required power level and efficiently produce plutonium.[189] Reactor D was started on 17 December 1944 and Reactor F on 25 February 1945.[190]

Separation process

Meanwhile, the chemists considered how plutonium could be separated from uranium when its chemical properties were not known. Working with the minute quantities of plutonium available at the Metallurgical Laboratory in 1942, a team under Charles M. Cooper developed a lanthanum fluoride process which was chosen for the pilot separation plant. A second separation process, the bismuth phosphate process, was subsequently developed by Seaborg and Stanly G. Thomson.[191] Greenewalt favored the bismuth phosphate process due to the corrosive nature of lanthanum fluoride, and it was selected for the Hanford separation plants.[192] Once X-10 began producing plutonium, the pilot separation plant was put to the test. The first batch was processed at 40% efficiency but over the next few months this was raised to 90%.[178]

At Hanford, top priority was initially given to the installations in the 300 area: buildings for testing materials, preparing uranium, and assembling and calibrating instrumentation. One of the buildings housed the canning equipment for the uranium slugs, while another contained a small test reactor. Notwithstanding its priority, work on the 300 area fell behind schedule due to the unique and complex nature of the facilities, and wartime shortages of labor and materials.[193]

Early plans called for the construction of two separation plants in each of the areas known as 200-West and 200-East. This was subsequently reduced to two, the T and U plants, in 200-West and one, the B plant, at 200-East.[194] Each separation plant consisted of four buildings: a process cell building or "canyon" (known as 221), a concentration building (224), a purification building (231) and a magazine store (213). The canyons were each 800 feet (240 m) long and 65 feet (20 m) wide. Each consisted of forty 17.7-by-13-by-20-foot (5.4 by 4.0 by 6.1 m) cells.[195]

Work began on 221-T and 221-U in January 1944, with the former completed in September and the latter in December. The 221-B building followed in March 1945. Because of the high levels of radioactivity involved, work in the separation plants had to be conducted by remote control using closed-circuit television, something unheard of in 1943. Maintenance was carried out with the aid of an overhead crane and specially designed tools. The 224 buildings were smaller because they had less material to process, and it was less radioactive. The 224-T and 224-U buildings were completed on 8 October 1944, and 224-B followed on 10 February 1945. The purification methods that were eventually used in 231-W were still unknown when construction commenced on 8 April 1944, but the plant was complete and the methods were selected by the end of the year.[196] On 5 February 1945, Matthias hand-delivered the first shipment of 80 g of 95%-pure plutonium nitrate to a Los Alamos courier in Los Angeles.[190]

Weapon design

In 1943, development efforts were directed to a gun-type fission weapon with plutonium called Thin Man. Initial research on the properties of plutonium was done using cyclotron-generated plutonium-239, which was extremely pure but could only be created in very small amounts. Los Alamos received the first sample of plutonium from the Clinton X-10 reactor in April 1944 and within days Emilio Segrè discovered a problem: the reactor-bred plutonium had a higher concentration of plutonium-240, resulting in up to five times the spontaneous fission rate of cyclotron plutonium.[197]

This rendered it unsuitable for use in a gun-type weapon, for the plutonium-240 would start the chain reaction too soon, causing a predetonation that would disperse the critical mass after a minimal amount of plutonium had fissioned (a fizzle). A higher-velocity gun was suggested but found to be impractical. The possibility of separating the isotopes was also considered and rejected, as plutonium-240 is even harder to separate from plutonium-239 than uranium-235 from uranium-238, and attempting it "would postpone the weapon indefinitely".[198]

Work on an alternative method of bomb design, known as implosion, had begun earlier under the direction of the physicist Seth Neddermeyer. Implosion used explosives to crush a subcritical sphere of fissile material into a smaller and denser form. The critical mass is assembled in much less time than with the gun method. When the fissile atoms are packed closer together, the rate of neutron capture increases,[199] so it also makes more efficient use of fissionable material.[200] Neddermeyer's 1943 and early 1944 investigations showed promise, but also made it clear that an implosion weapon was more complex than the gun-type design from both a theoretical and an engineering perspective.[201] In September 1943, John von Neumann, who had experience with shaped charges, proposed using a spherical configuration instead of the cylindrical one that Neddermeyer was working on.[202]

An accelerated effort on the implosion design, codenamed Fat Man, began in August 1944 when Oppenheimer implemented a sweeping reorganization of the Los Alamos laboratory to focus on implosion.[203] Two new groups were created at Los Alamos to develop the implosion weapon, X (for explosives) Division headed by explosives expert George Kistiakowsky and G (for gadget) Division under Robert Bacher.[204][205] The new design featured explosive lenses that focused the implosion into a spherical shape.[206] The design of lenses turned out to be slow, difficult and frustrating.[206] Various explosives were tested before settling on composition B and baratol.[207] The final design resembled a soccer ball, with 20 hexagonal and 12 pentagonal lenses, each weighing about 80 pounds (36 kg). Getting the detonation just right required fast, reliable and safe electrical detonators, of which there were two for each lens for reliability.[208] They used exploding-bridgewire detonators, a new invention developed at Los Alamos by a group led by Luis Alvarez.[209]

To study the behavior of converging shock waves, Robert Serber devised the RaLa Experiment, which used the short-lived radioisotope lanthanum-140, a potent source of gamma radiation. The gamma ray source was placed in the center of a metal sphere surrounded by the explosive lenses, which in turn were inside in an ionization chamber. This allowed the taking of an X-ray movie of the implosion. The lenses were designed primarily using this series of tests.[210] In his history of the Los Alamos project, David Hawkins wrote: "RaLa became the most important single experiment affecting the final bomb design".[211]

Within the explosives was an aluminum pusher, which provided a smooth transition from the relatively low-density explosive to the next layer, the tamper of natural uranium. Its main job was to hold the critical mass together as long as possible, but it would also reflect neutrons into the core and some of its uranium would fission. To prevent predetonation by an external neutron, the tamper was coated in a thin layer of neutron-absorbing boron.[208] A polonium-beryllium modulated neutron initiator, known as an "urchin",[212] was developed to start the chain reaction at precisely the right moment.[213] This work on the chemistry and metallurgy of radioactive polonium was directed by Charles Allen Thomas of the Monsanto Company and became known as the Dayton Project.[214] Testing required up to 500 curies per month of polonium, which Monsanto was able to deliver.[215] The whole assembly was encased in a duralumin bomb casing to protect it from bullets and flak.[208]

The ultimate task of the metallurgists was to determine how to cast plutonium into a sphere. The difficulties became apparent when attempts to measure the density of plutonium gave inconsistent results. At first contamination was suspected, but it was soon determined that there were multiple allotropes of plutonium.[216] The brittle α phase that exists at room temperature changes to the plastic β phase at higher temperatures. Attention then shifted to the even more malleable δ phase that normally exists in the 300 °C to 450 °C range. It was found that this was stable at room temperature when alloyed with aluminum, but aluminum emits neutrons when bombarded with alpha particles, which would exacerbate the pre-ignition problem. The metallurgists then hit upon using a plutonium-gallium alloy, which stabilized the δ phase and could be hot pressed into the desired spherical shape. As plutonium was found to corrode readily, the sphere was coated with nickel.[217]

The work proved dangerous. By the end of the war, half the chemists and metallurgists had to be removed from work with plutonium when unacceptably high levels of the element was detected in their urine.[218] A minor fire at Los Alamos in January 1945 led to a fear that a fire in the plutonium laboratory might contaminate the whole town, and Groves authorized the construction of a new facility for plutonium chemistry and metallurgy, which became known as the DP-site.[219] The hemispheres for the first plutonium pit (or core) were produced and delivered on 2 July 1945. Three more hemispheres followed on 23 July and were delivered three days later.[220]

In contrast to the plutonium Fat Man, the uranium gun-type Little Boy weapon was straightforward if not trivial to design. Overall responsibility for it was assigned to Parsons's Ordnance (O) Division, with the design, development, and technical work at Los Alamos consolidated under Lieutenant Commander Francis Birch's group. The gun-type design now had to work with enriched uranium only, and this allowed the design to be greatly simplified. A high-velocity gun was no longer required, and a simpler weapon was substituted.[221][222]

Research into the Super was also pursued, although it was considered secondary to the development of a fission bomb. The effort was directed by Teller, who was its most enthusiastic proponent.[223] The F-1 (Super) Group calculated that burning 1 cubic meter (35 cu ft) of liquid deuterium would release the energy of 10 megatonnes of TNT (42 PJ), enough to devastate 1,000 square miles (2,600 km2).[224] In a final report on the Super in June 1946, Teller remained upbeat about the prospect of it being successfully developed, although that opinion was not universal.[225]

Trinity

Because of the complexity of an implosion-style weapon, it was decided that, despite the waste of fissile material, a full-scale nuclear test was required. Oppenheimer codenamed it "Trinity".[226] In March 1944, planning for the test was assigned to Kenneth Bainbridge, who selected the Alamogordo Bombing Range for the test site.[227] A base camp was constructed with barracks, warehouses, workshops, an explosive magazine and a commissary.[228] A pre-test explosion was conducted on 7 May 1945 to calibrate the instruments. A wooden test platform was erected 800 yards (730 m) from Ground Zero and piled with 100 short tons (91 t) of TNT spiked with nuclear fission products.[229][230]

Groves did not relish the prospect of explaining to a Senate committee the loss of a billion dollars worth of plutonium, so a cylindrical containment vessel codenamed "Jumbo" was constructed to recover the active material in the event of a failure. It was fabricated at great expense from 214 short tons (194 t) of iron and steel.[231] By the time it arrived, however, confidence in the implosion method was high enough, and the availability of plutonium was sufficient, that Oppenheimer decided not to use it. Instead, it was placed atop a steel tower 800 yards (730 m) from the weapon as a rough measure of the explosion's power. Jumbo survived, although its tower did not, adding credence to the belief that Jumbo would have successfully contained a fizzled explosion.[232][229]

For the actual test, the weapon, nicknamed "the gadget", was hoisted to the top of a 100-foot (30 m) steel tower, as detonation at that height would give a better indication of how the weapon would behave when dropped from a bomber. Detonation in the air maximized the energy applied directly to the target and generated less nuclear fallout. The gadget was assembled under the supervision of Norris Bradbury at the nearby McDonald Ranch House on 13 July, and precariously winched up the tower the following day.[233]

At 05:30 on 16 July 1945 the gadget exploded with an energy equivalent of around 20 kilotons of TNT, leaving a crater of Trinitite (radioactive glass) in the desert 250 feet (76 m) wide. The shock wave was felt over 100 miles (160 km) away, and the mushroom cloud reached 7.5 miles (12.1 km) in height. It was heard as far away as El Paso, Texas, so Groves issued a cover story about an ammunition magazine explosion at Alamogordo Field involving gas shells.[234][235]

Oppenheimer later claimed that, while witnessing the explosion, he thought of a verse from the Hindu holy book, the Bhagavad Gita (XI,12):

कालोऽस्मि लोकक्षयकृत्प्रवृद्धो लोकान्समाहर्तुमिह प्रवृत्तः। ऋतेऽपि त्वां न भविष्यन्ति सर्वे येऽवस्थिताः प्रत्यनीकेषु योधाः॥११- ३२॥ |

together with verse (XI,32), which he translated as "Now I am become Death, destroyer of worlds".[238][239][h]

The test was significantly more successful than had been anticipated; this was immediately cabled to Stimson, who was then at the Potsdam Conference, and Groves hastily prepared a lengthier report sent via courier. Truman was powerfully and positively affected by the news. Stimson noted in his diary that when he shared it with Churchill, Churchill remarked: "Now I know what happened to Truman yesterday. I couldn't understand it. When he got to the meeting after having read this report, he was a changed man. He told the Russians just where they got on and off and generally bossed the whole meeting."[241]

Personnel

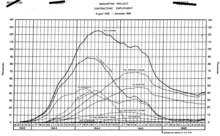

At its peak in June 1944, the Manhattan Project employed about 129,000 workers, of whom 84,500 were construction workers, 40,500 were plant operators and 1,800 were military personnel. As construction activity declined, the workforce fell to 100,000 a year later, but the number of military personnel increased to 5,600. Procuring the required numbers of workers, especially highly skilled workers, in competition with other vital wartime programs proved very difficult.[242] Due to high turnover, over 500,000 people worked on the project.[243] Most African Americans were employed in low-level jobs, but there were a few African-American scientists and technicians.[244]

In 1943, Groves obtained a special temporary priority for labor from the War Manpower Commission. In March 1944, both the War Production Board and the War Manpower Commission gave the project their highest priority.[245] The Kansas commission director stated that from April to July 1944 every qualified applicant in the state who visited a United States Employment Service office was urged to work at the Hanford Site. No other job was offered until the applicant definitively rejected the offer.[246] Tolman and Conant, in their role as the project's scientific advisers, drew up a list of candidate scientists and had them rated by scientists already working on the project. Groves then sent a personal letter to the head of their university or company asking for them to be released for essential war work.[247]

One source of skilled personnel was the Army itself, particularly the Army Specialized Training Program. In 1943, the MED created the Special Engineer Detachment (SED), with an authorized strength of 675. Technicians and skilled workers drafted into the Army were assigned to the SED. Another source was the Women's Army Corps (WAC). Initially intended for clerical tasks handling classified material, the WACs were soon tapped for technical and scientific tasks as well.[248] On 1 February 1945, all military personnel assigned to the MED, including all SED detachments, were assigned to the 9812th Technical Service Unit, except at Los Alamos, where military personnel other than SED, including the WACs and Military Police, were assigned to the 4817th Service Command Unit.[249]

An associate professor of Radiology at the University of Rochester School of Medicine, Stafford L. Warren, was commissioned as a colonel in the United States Army Medical Corps, and appointed as chief of the MED's Medical Section and Groves' medical advisor. Warren's initial task was to staff hospitals at Oak Ridge, Richland and Los Alamos.[250] The Medical Section was responsible for medical research, but also for the MED's health and safety programs. This presented an enormous challenge, because workers were handling a variety of toxic chemicals, using hazardous liquids and gases under high pressures, working with high voltages, and performing experiments involving explosives, not to mention the largely unknown dangers presented by radioactivity and handling fissile materials.[251] Yet in December 1945, the National Safety Council presented the Manhattan Project with the Award of Honor for Distinguished Service to Safety in recognition of its safety record. Between January 1943 and June 1945, there were 62 fatalities and 3,879 disabling injuries—about 62 percent below the rate of private industry.[252]

Secrecy

The Manhattan Project operated under a mandate of "absolute secrecy" from Roosevelt, meaning that the very existence of the project itself was to be kept secret. This proved a daunting task given the amount of knowledge and speculation about nuclear fission that existed prior to the Manhattan Project, the huge numbers of people involved, and the scale of the facilities.[253] Groves adopted an extreme version of compartmentalization (the need-to-know policy):

Compartmentalization of knowledge, to me, was the very heart of security. My rule was simple and not capable of misinterpretation—each man should know everything he needed to know to do his job and nothing else. Adherence to this rule not only provided an adequate measure of security, but it greatly improved over-all efficiency by making our people stick to their knitting. And it made quite clear to all concerned that the project existed to produce a specific end product—not to enable individuals to satisfy their curiosity and to increase their scientific knowledge.[254]

This clashed with the norms of many of the scientists involved, who claimed that science could not operate successfully under such requirements. The Manhattan Project officials also had difficulty with journalists, Congressmen, federal officials who were not "in the know", residents near local sites, judges adjudicating land claims, and other sources of speculation, prying, and leaks, along with concerns about espionage and sabotage. Groves relied on the FBI and his own autonomous G-2 intelligence unit to investigate potential security violations. Ultimately over 1,500 "loose talk" cases were investigated during the war. Even Harry Truman was not informed about the project while he was vice president, and only learned about it after Roosevelt's death.[253]

Because of its relative success at keeping the story out of newspapers, Byron Price, head of the Office of Censorship, ultimately designated the Manhattan Project "the best-kept secret of the war".[255] In 1945 Life estimated that before the Hiroshima and Nagasaki bombings "probably no more than a few dozen men in the entire country knew the full meaning of the Manhattan Project, and perhaps only a thousand others even were aware that work on atoms was involved." The magazine wrote that the more than 100,000 others employed with the project "worked like moles in the dark". Warned that disclosing the project's secrets was punishable by 10 years in prison or a fine of US$10,000 (equivalent to $169,000 in 2023), they monitored "dials and switches while behind thick concrete walls mysterious reactions took place" without knowing the purpose of their jobs.[256][257][258]

In December 1945 the US Army published a secret report assessing the security apparatus surrounding the Manhattan Project. The report states that the project was "more drastically guarded than any other highly secret war development." The surrounding security infrastructure was so vast and thorough that in the early days of the project in 1943, investigators vetted 400,000 potential employees and 600 companies for potential security risks.[259]

Censorship

Zdroj:https://en.wikipedia.org?pojem=Manhattan_ProjectText je dostupný za podmienok Creative Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších podmienok. Podrobnejšie informácie nájdete na stránke Podmienky použitia.

Antropológia

Aplikované vedy

Bibliometria

Dejiny vedy

Encyklopédie

Filozofia vedy

Forenzné vedy

Humanitné vedy

Knižničná veda

Kryogenika

Kryptológia

Kulturológia

Literárna veda

Medzidisciplinárne oblasti

Metódy kvantitatívnej analýzy

Metavedy

Metodika

Text je dostupný za podmienok Creative

Commons Attribution/Share-Alike License 3.0 Unported; prípadne za ďalších

podmienok.

Podrobnejšie informácie nájdete na stránke Podmienky

použitia.

www.astronomia.sk | www.biologia.sk | www.botanika.sk | www.dejiny.sk | www.economy.sk | www.elektrotechnika.sk | www.estetika.sk | www.farmakologia.sk | www.filozofia.sk | Fyzika | www.futurologia.sk | www.genetika.sk | www.chemia.sk | www.lingvistika.sk | www.politologia.sk | www.psychologia.sk | www.sexuologia.sk | www.sociologia.sk | www.veda.sk I www.zoologia.sk